CLASSES

Take a class at Fox Valley Tech for fun, personal enrichment or career development. Find classes in any location during any time of the day. We have hundreds of classes to fit your budget, schedule and learning style.

CATEGORIES

Sorry, no results were found. Please check back later.

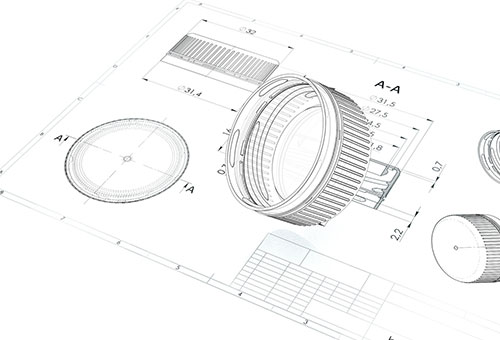

Focuses on the interpretation of machine drawings. Students study isometric and orthographic views on drawing and develop simple working drawings. Topics include dimensions, internal and external threads, holes, bores, fillets, radii, surfaces, planes, metric and geometric dimensioning and tolerancing.

Provides information regarding relevant laws and regulations, relevant scientific principles and their application, and best management practices of hazardous materials.

Helps the learner to develop skills in designing work stations, developing better work methods, establishing work standards, balancing assembly lines, and estimating labor costs. The time study techniques the learner will use include predetermined time standard systems, stopwatch, and work sampling.

Introduces the culture and outlines the characteristics of an organization that has embraced lean principles. Provides details of planning and facilitating process improvement events, including value stream mapping.

Presents a comprehensive overview of the fundamental manufacturing process families. Learners focus first on how the processes move from a primary process of operation to the secondary process; then examine the tools and tooling used in manufacturing, forming, and casting techniques and their application, as well as material removal processes.

Introduces types of and reasons for audits. Students learn how to conduct an internal audit and to describe and apply various auditing tools and techniques such as checklists, interview techniques, record/document review, and tracing.

Provides an overview of the three basic welding processes, i.e. wire feed welding (GMAW, FCAW), stick welding (SMAW), and TIG welding (GTAW). The lab work will be equally divided among the welding processes.